Getting The Most From Form, Fill & Seal Equipment

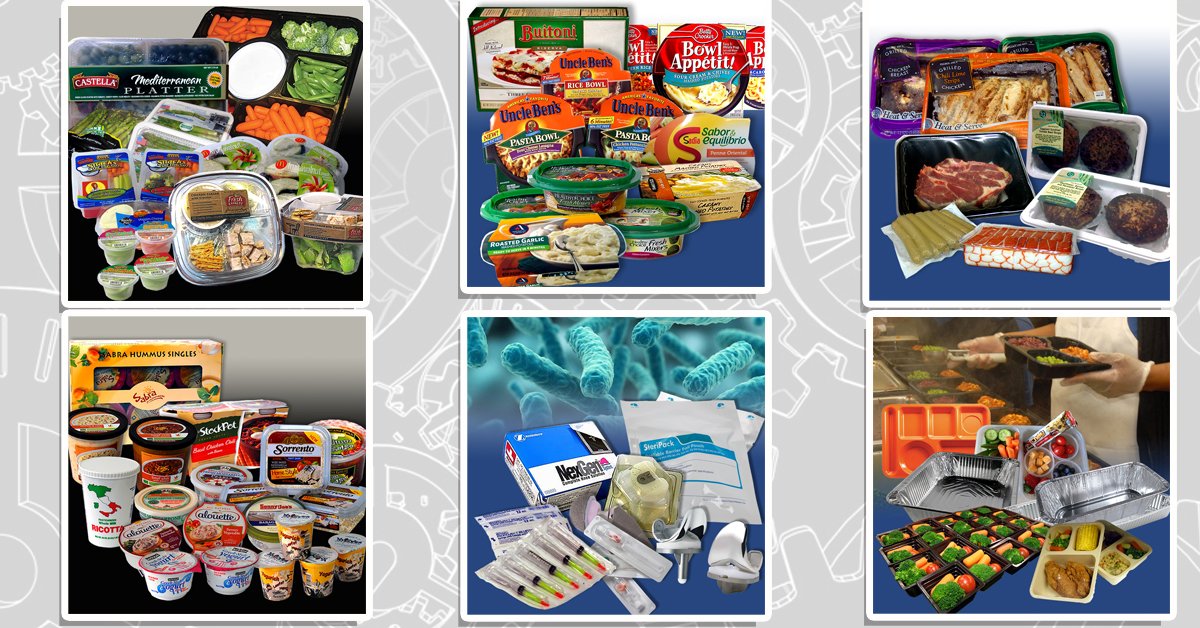

For many brands, horizontal form-fill-seal (FFS) equipment represents a significant investment. FFS machines can be the most expensive machine on the packaging line. To maximize return on the investment, companies re-purpose machines for packaging a range of products. This makes quick tooling changes an attractive feature.

Over the last few years, ORICS Industries has worked to ease changeover in our FFS-30 for changing package sizes. We understand that our customers have been looking for ways to make it more efficient.

The ease of changeover can depend upon how easy it is to get tools in and out. Tools are often heavy and require a lot of muscle to remove and replace. This can result in injury risks, such as strained backs, broken fingers, etc. The risk of damage to tools is also heightened.

Changeover varies in complexity. The change may simply be to the packaging material, maintaining the same packaging footprint. Or, an entirely new package size or style may be needed. The amount of tooling changes depends on the degree of packaging change.

Tooling that can be changed includes forming dies, sealing platens, and cutting knives. There are control issues that may need to be changed to accommodate different packages, such as changing temperature, pressure, and index length. And there are peripheral issues associated with things like lot coders and in-line printers to changeover.

Should You Change?

Many companies that employ FFS machinery do so because they want better productivity and lower costs. Higher volumes may justify a dedicated packaging line, thus obviating the need for routine changeover. A daily production on FFS could be more than 100,000 packages, depending on the product being manufactured. Thus, the goal is often not to change out tooling.”

There may be other reasons for foregoing changeover. Validation of FFS is directly tied into forming tooling, loading, printing, sealing, and cutting. This process, when properly done, can take up to a week or more per tooling set. Once this activity is successfully completed, manufacturers would not want to upset the apple cart by making changes. This is also reinforced by the fact that FFS runs are generally three shifts for many weeks, sometimes months.

A partial if not complete validation would be required every time tooling is changed out. Depending upon the actual situation, the cost of the re-validation could exceed the potential cost savings of ‘quick-change’ tooling.