Expanding Markets In Packaging

Expanding markets are driving new innovation

Increasing advancement in packaging technology for variety of end-use application increases the expectations that the demand will grow further in the next ten years. Manual tasks are quickly being replaced by automatic packaging machines in many industries. Most of the demand for packaging machinery is generated from the food & beverages industry due to significant growth in the consumption of the packaged food.

New Formats Create The Need For New Solutions.

New packaging formats in the e-commerce and food & beverages industry are gaining popularity which has created the need for development of product-specific packaging machinery. Packaging machinery manufacturers are innovating in terms of increasing the efficiency of existing products and the development of customized products according to the requirement of customers.

Global demand for packaging machinery is growing and light speed. ORICS Industries is leading the way in terms of offering highly sophisticated and automated packaging machinery.

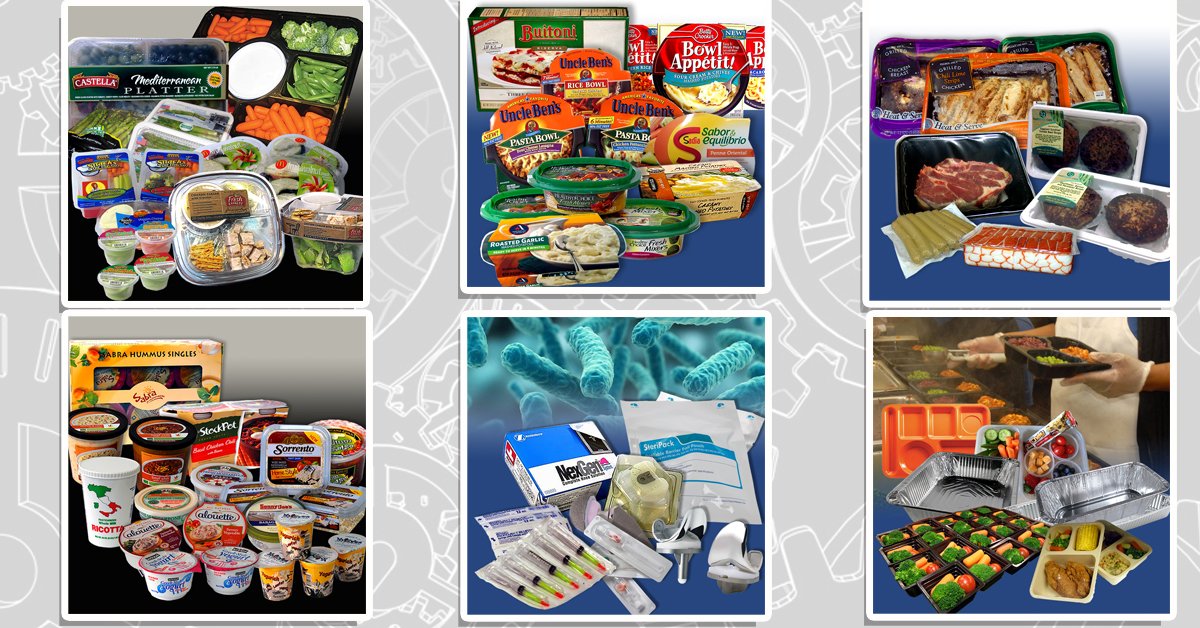

These packaging machines are widely used in different end-use industries, prominently in the food & beverages industry, for products that are shipped in cups, tubs, trays, jars, bowls, etc. Form fill and seal machines are increasingly gaining traction in the emerging market due to the integration of three processes in a single system.

More and more end-use companies are demanding integrated packaging machinery rather than purchasing different machinery for a specific application. Integration of packaging machinery has also propelled the demand for turnkey packaging machinery globally.

At ORICS Industries, we’re finding new markets such as cosmetics, cannabis, tissue, and all sorts of consumer goods are increasing demand for integrated automation solutions. Are key markets remain Fresh Produce, Meat, Poultry & Seafood, Dairy/ Deli, Ready Meals, Medical & Pharmaceutical and Institutional distribution.

At ORICS Industries, we’re finding new markets such as cosmetics, cannabis, tissue, and all sorts of consumer goods are increasing demand for integrated automation solutions. Are key markets remain Fresh Produce, Meat, Poultry & Seafood, Dairy/ Deli, Ready Meals, Medical & Pharmaceutical and Institutional distribution.

Find out how we can help you to grow and stay competitive in your market. Call us for a free, no-obligation consultation and let’s discuss how we can make your packaging the best it can be.