3 Advantages of Servo-Driven Packaging Systems

Compared with traditional mechanical packaging machines, servo-controlled machines offer 3 distinct advantages.

Today, machinery construction designers and manufacturers are facing special challenges that include rapid format changes, versatility, security, flexibility and availability. Much of this is driven by changing tastes of the consumer, and to the need to combine different packaging production processes on the same machine to maximize investments. These goals are easy to achieve with the right servo drives and motion control systems.

Today’s machines need a compact footprint. Servos can provide a much higher torque-to-volume ratio than other technologies. Servos are also available in a wide variety of sizes, making the processes around machines easier and faster. Servo drives and electronic here motion controllers like the enable very simple format changeovers. Electronically synchronized servo drives ensure an optimized dynamic response in every phase of production and provide very consistent results.

There are 3 distinct advantages to to servo-driven systems:

1. Ease of Programming

Motion control programming in 3 steps

- Graphically configure the drive.

- Select the motion functions using technology objects.

- Programming with PLC open and proven machine libraries.

2. Proven application configurations

The technology makes it possible to download ready-to-apply function configurations, for tooling that includes cross-cutting, gearing, flying saw, jog path, load sharing, positioning, rotary knife, splice control, synchronicity and more.

3. Improved Safety

Implementing safety in a conventional machine can be cumbersome and costly. With integration of safety technology, the safety functions are directly integrated into a servo drive with no need for additional hardware. Functional safety can be expanded for use with different applications in full compliance with standards.

Because the architecture is based on high-speed industrial Ethernet networks special or detailed diagnostics of all components can be implemented within a network. Drives can be commissioned and fully diagnosed without requiring any additional software.

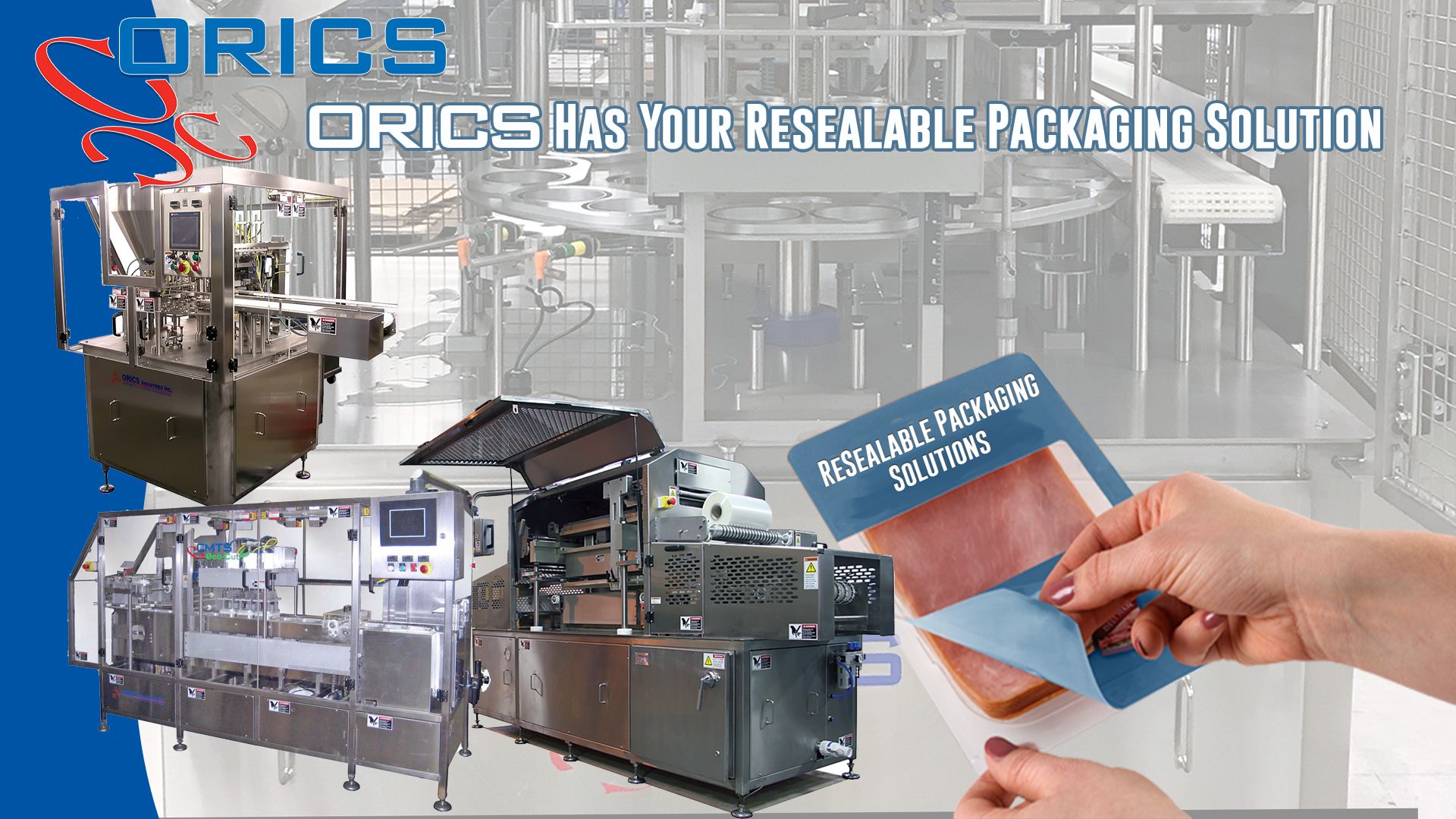

ORICS has the right servo-driven system for your needs. Let’s talk about your project, click here.